gravimetric feeder system Equipment principle

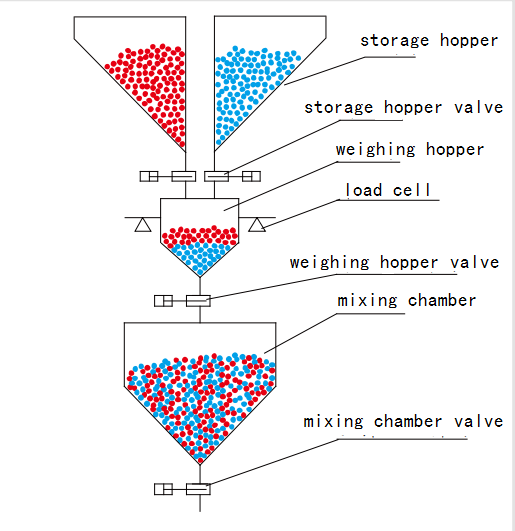

Equipment introduction: It can realize automatic feeding and storage of incoming materials and automatic weighing and mixing;

There is a formula system, material report system;

The intermediate warehouse for the finished product can be stored in the intermediate warehouse in batches;

When needed, all equipment can be supplied through the centralized feeding system;

The whole process can be controlled by one person.

Features and advantages:

Significantly reduce operating staff;

Reduce employee labor;

The weighing system has higher precision and less equipment failure rate;

Have complete system design experience.

1. Unloading system;

2. Conveying system;

3. Metering and batching system;

4. Mixing unit;

5. Material storage system;

6. Dust removal system;

7. Central control system;

8. Auxiliary equipment.gravimetric feeder system、gravimetric dosing、gravimetric blender、plastic gravimetric blender |