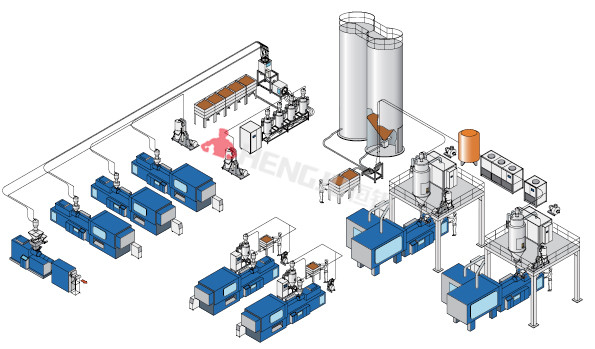

Automatic Conveying System Equipment principle

The central feeding system adopts vacuum conveying method, and the plastic raw materials are transferred from the storage silo to the central dosing and mixing system (if necessary) through the centralized pipeline system, and then the well-mixed materials are loaded to the central dehumidifying and drying system, and finally the dried raw materials are delivered to each injection molding machine.

The central feeding system adopts the design method of "one machine and one pipe" to ensure that the air of the entire system conveys the raw materials to prevent the moisture coming back. At the same time, the conveying in each pipeline is smooth, and there is no material blocking. Under vacuum pressure, the dust in the raw materials will be filtered through the dust filtration system, which helps to improve the quality of the final products.

Centralized Conveying System |