| Gravimetric Dosing Unit Details description |

|

| product name:Gravimetric Dosing Unit |

| release time:2020-05-13 14:20:06 |

| Numbering:HGB-200 |

| Brand:HENGJU |

| Price:¥USD 5300 |

| simple description:Gravimetric blender also called as gravimetric dosing system or gravimetric batch blender, is an industrial device used in plastic production industry to dose or weigh two or more components and then mix them together prior to processing in the molding machines. |

| weight :200.00 |

| unit weight:KG |

| characteristic:For Plastic Material Dosing and Mixing |

| patent:Automatic Weighing and Mixing Control System |

| manufacturer:HENGJU |

| Producing country:CHINA |

| Product alias:Gravimetric Batch Blender |

|

| Gravimetric Dosing Unit Product introduction |

|

Gravimetric Dosing Unit parameter

| Model |

HGB-200 |

| Qty of Group number |

4 |

| Mixing capacity(kg/hr) |

200 |

| Batch weight(kg) |

2.2 |

| Main material mixing range(%) |

5~100 |

| Additive mixing range(%) |

0.5~10 |

| Main hopper volume(L) |

32 |

| Additive hopper volume(L) |

32 |

| Mixing barrel volume(L) |

20 |

| Power supply(V/Hz) |

1Φ |

| 230/50 |

| Total power(kW) |

0.25 |

| Compressed air (kgf/cm2) |

6~8 |

| Max. noise level(dB) |

<75 |

Note:

1) Dosing accuracy are refer to each ingredient accuracy ;

2) standard valves are not suitable powder dosing;

3) Max .output of each model and dosing accuracy are based on the data from bulk density 0.8 ,dia. 3~4mm pellets in a test criteria of continuous running.

We reserve the right to change specifications without prior notice .Gravimetric Batch Blender |

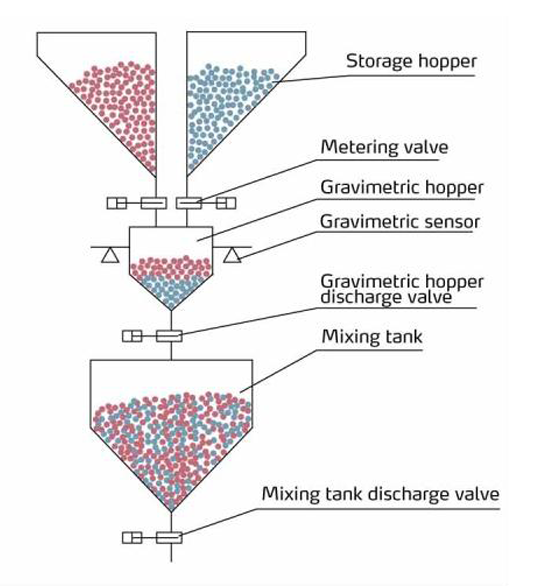

Gravimetric Dosing Unit Equipment principle

A gravimetric blender has two or more hoppers arranged above a weigh-pan which is controlled by a very sensitive load cell. And the hoppers will open and close under control of the slide-gate valve. Once the blender is turned on and the recipe is selected, it will dose and mix materials automatically.

For instance, if you select recipe A which is comprised of natural resin 90%, regrind 8%, color 2%, and you preset the batch weight as 1000g, then the PLC inside the blender will control the open/close of the hopper valves in order. First natural resin hopper open and resin flows down into the weigh-pan until it reaches 900g, then the valve closes. Secondly, the regrind hopper valve opens and regrind flows down into the weigh-pan until it reaches the amount of 80g, then the valve closes, and the same as the color. Once the batch has been weighed out, the contents of the weigh-pan are dispensed into a mixing chamber where they are blended. The resulting mixture exits the base of the mixing chamber into the processing machine. Gravimetric Batch Blender |

Gravimetric Dosing Unit application

Now more and more customers are introducing gravimetric blender to their production for LED, auto parts, non-woven bag, film, bottles & containers, all injection parts, cables, and wire, etc. And the areas are expanding.

Hereafter are some application cases for your reference:

Gravimetric Batch Blender |

Gravimetric Dosing Unit Precautions

Before carrying out machine-related operations, the person who intends to operate and maintain the machine must read and understand the relevant contents of this operating manual, especially the safety-related parts.

The following safety instructions are particularly important to avoid personal injury and property damage:

1) Please ensure that there are no tools, other equipment and objects in the workstation. Do not place tools or other objects on the device. Because vibration may cause them to fall off the device, causing personal injury and / or property damage.

2) Please keep the device and the workplace clean and tidy, and ensure that the particles are not scattered on the ground. This may cause staff to slip and be injured.

3) When cleaning or servicing the blender, wear work gloves. Work gloves will protect your hands and fingers from being broken.

4) When operating this machine, be sure to abide by the safety regulations of the local government. Product alias:Gravimetric Batch Blender |

|

|