| plastic industrial central conveying system Details description |

|

| product name:plastic industrial central conveying system |

| release time:2020-05-08 09:54:40 |

| Numbering:depends |

| Brand:hengju |

| Price:¥plastic industrial central conveying system |

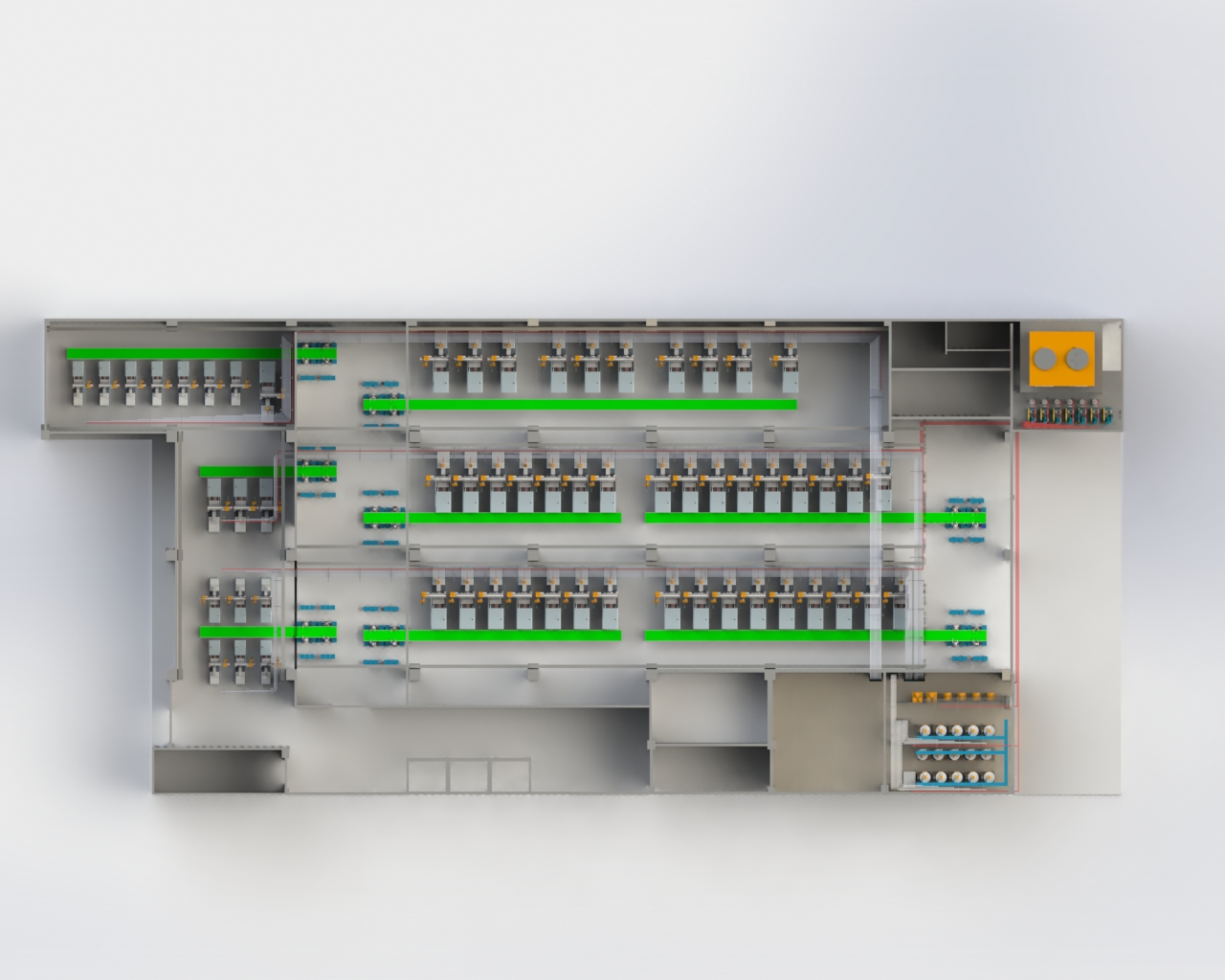

| simple description:The central feeding system is designed for the production of plastic products in the injection workshop, enabling uninterrupted unmanned continuous molding operations. The variety of raw materials and the combined use of multi-color materials can be changed as needed to automate the coloring process. The system can regenerate and use the cold injection material in a fully automatic way, can control all the feeding equipment, and prevent the occurrence of blockages in the storage bin. It is fully automated by setting up a central monitoring station. |

| weight :0.00 |

| unit weight:dependes |

| characteristic:automatic |

| patent:CE/ISO |

| manufacturer:HENGJU |

| Producing country:China |

| Product alias:centralized feeding system, centralized conveying system |

|

| plastic industrial central conveying system Product introduction |

|

plastic industrial central conveying system parameter

| Roots Blower Parameters |

| Modle |

HFV-10 |

HFV-15 |

HFV-20 |

HFV-30 |

HFV-40 |

HFV-50 |

HFV-75 |

| Caliber |

3'' |

4'' |

5'' |

5'' |

6'' |

8'' |

10'' |

electric motor |

10HP |

15HP |

20HP |

30HP |

40HP |

50HP |

75HP |

| |

|

|

|

|

|

|

| Pressure |

-4000 |

-4000 |

-5000 |

-5000 |

-5000 |

-5000 |

-5000 |

| Wind |

6 |

8 |

13 |

17 |

22 |

30 |

50 |

| High presssure fan specifications |

| HBModel |

UNIT |

720H16 |

720H26 |

720H37 |

720H47 |

720H57 |

720H67 |

720H77 |

| Rated power |

KW |

2.2 |

3.0 |

4.3 |

5.5 |

7.5 |

5.5 |

7.5 |

| The Maximum wind pressure |

Mbar |

290 |

300 |

380 |

420 |

450 |

420 |

450 |

| Vacuum pump |

Mbar |

-260 |

-270 |

-360 |

-370 |

-380 |

-400 |

-460 |

| Maximum air flow |

m³/h |

270 |

318 |

320 |

530 |

530 |

320 |

320 |

| Normal Operating Pressure |

Mbar |

-240 |

-250 |

-340 |

-350 |

-360 |

-420 |

-40 |

| Voltage |

|

3Φ 220V 3Φ 380V |

controller

1.Digitalized and intelligent PLC + touch screen for operation interface and running status display panel. Simple man-machine dialogue makes

2.Monitored by someone or connected to a PC:

3.The display screen can clearly display the machine status, the rotating state of the drying hopper and the barrel, such as startup, full

4.Beautiful and durable appearance, small size, lless ocupied space;

5.There are full and lack of materials display alarm;

6.Various feeding specifications can be set;

7.Touch screen color interface vision;

8.Have memory function;

9.Fault display function.

combined pulsating cyclone and dust collection

1.After each single suction, the air filter is reversely cleaned to avoid the trouble of filter blockage. It is equipped with a pressure storage tank and installed with overpressure protection to collect fine dust and protect high-pressure fans.

2.Using Taiwan Electromagnetic valve;

3.The filter barrel is made of stainless steel, with a paper filter inside the filter, and movable casters are installed at the bottom;

4.Equipped with valve design, filter can be cleaned without stopping

Material storage tank

centralized feeding system, centralized conveying system |

plastic industrial central conveying system Equipment principle

The central feeding system adopts vacuum conveying method, and the plastic raw materials are transferred from the storage tank to the central dehumidification and drying system through a centralized pipeline system, and then the dried raw materials are transferred to each injection molding machine. The central feeding system adopts the design method of "one machine and one pipe" to ensure that the air of the entire system conveys the raw materials to prevent the moisture from drying and drying. At the same time, the operation of each transmission is stable, and no blocking phenomenon occurs. It is used in conjunction with the central dehumidification and drying system, which can be used to clean the pipeline after the dehumidification, drying and circulation, to ensure that there is no residual particulate material in the pipeline. Consistent. Under the vacuum negative pressure, the dust in the raw materials will be filtered through the dust filtration system, which helps to improve the quality of the molded products.

Parts of central conveying system

controller, high pressure positive blower HB, combined pulsating cyclone and dust collection, material storage tank, Material distribution station, suction box, air cut-off valva, pipeline connector and so on.

features:

1. Efficient: The central feeding system can realize the automatic supply of various raw materials to any injection molding processing equipment in multiple chambers, which can include the drying processing of raw materials, color matching processing, and the utilization of proportionally crushed recycled materials. Automation control, monitoring, etc., and can meet the 24-hour non-stop production needs.

Second, energy saving: the central feeding system is easy to operate, and only a few people can control the feeding requirements of the entire injection molding plant, thereby reducing a lot of labor costs. Secondly, the raw material belt and corresponding auxiliary equipment beside the injection molding machine are reduced, and the space utilization rate is improved. In addition, due to the use of the central feeding method, correspondingly reducing a lot of stand-alone equipment, it also saves electricity and reduces maintenance costs.

3. Personalization: The central feeding system can achieve different users, different workshop characteristics, and different requirements for the use of raw materials. Can be designed according to actual needs to optimize the program.

Fourth, the image of a modern factory: the central feeding system will minimize the pollution of raw materials and dust on injection molding production, so that it can maintain a clean production workshop, and the central feeding system has a unique centralized dust recovery system, which is more convenient and clean. The environmental protection effect is to reach the standard of 100,000 clean room operation requirements, and reduce the noise, and finally can realize the unmanned automated production workshop, and establish the image of modern factory management.

centralized feeding system, centralized conveying system |

plastic industrial central conveying system application

centralized feeding system, centralized conveying system |

plastic industrial central conveying system Precautions

1. Consider the requirements for raw materials of the plastic production process

2. Mixing and drying of raw materials

3. The amount of raw materials and the distance of transportation

4. Development planning and production requirements in the next few years

5. Meet the principle of practical economic stability

6. Choose a professional manufacturer

Product alias:centralized feeding system, centralized conveying system |

|

|